Universidad

SSS Clutch consulted with Comisión Federal de Electricidad in Mexico to retrofit a clutch into the existing installation to support the need for reactive power.

CTG Universidad is a two-unit combustion turbine plant commissioned in late 1970 by the Comisión Federal de Electricidad (CFE) on the north side of Monterrey, Mexico’s third-largest city and an important industrial centre. The two 14MW turbines were obsolete, used sparingly, and slated for demolition. However, portions of Monterrey began experiencing power restrictions caused by a lack of reactive power and that situation presented an opportunity for the plant.

By repurposing an old combustion turbine for use as a synchronous condenser to provide local reactive power, CFE significantly reduced local power supply limitations.

Before the retrofit, CFE was experiencing the effects of its industrial customers’ very high inductive power usage. The increased need for reactive power was evidenced by load-limited power lines and unacceptable line voltage drop. In fact, Mexico’s National Energy Control Center had identified reactive power–deficient zones on the Mexican grid. One of those zones was near Universidad in Monterrey. In previous years, the plant had produced the necessary reactive power when operating. The best and least expensive solution was identified as adding reactive power to the distribution lines closer to end users, thereby allowing additional real power to flow into the downtown Monterrey grid.

Before the retrofit, CFE was experiencing the effects of its industrial customers’ very high inductive power usage. The increased need for reactive power was evidenced by load-limited power lines and unacceptable line voltage drop. In fact, Mexico’s National Energy Control Center had identified reactive power–deficient zones on the Mexican grid. One of those zones was near Universidad in Monterrey. In previous years, the plant had produced the necessary reactive power when operating. The best and least expensive solution was identified as adding reactive power to the distribution lines closer to end users, thereby allowing additional real power to flow into the downtown Monterrey grid.

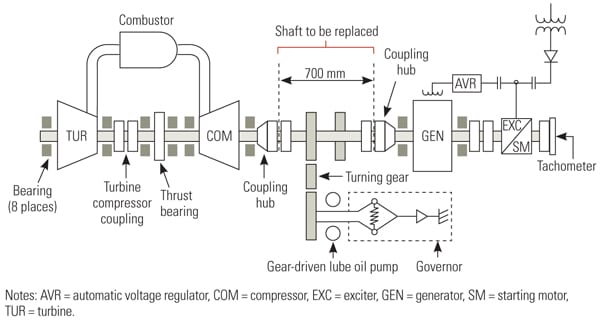

SSS Clutch Co. Inc. carried out a feasibility study on Unit 2 and concluded that it was possible to retrofit a special 160T SSS Clutch into the existing system between the compressor on the Brown Boveri BB11-L dual-fuel combustion turbine and the generator. The SSS Clutch assembly also needed to act as a flexible coupling able to absorb a certain amount of misalignment during power generation but able to disconnect during synchronous condenser operation.

The SSS Clutch includes a lock-in feature which allows the clutch to transmit torque from the starting motor system at the free end of the generator to the Gas Turbine to start the machine. The locking system is actuated through a simple solenoid valve controlling servos running on the main lubricating system at standard pressure. Locking and unlocking the clutch can be done at any time by the operation of this valve.

Universidad Marmaduke Award - Power Magazine (PDF)

The plant was recognised for it’s savvy repurposing of its assets and won the magazine's top honours … The Marmaduke Award