SSS Clutches enable fans, pumps, compressors and other industrial systems to be dual driven. The drive can be transferred from one prime mover to the other automatically at any speed. Dual driven systems can provide Energy Recovery, Redundancy, Maintenance during operation, Startup and Helper (boost) drives.

-

Fans

Industrial fans are high torque, relatively low speed drives that benefit from being dual driven as they often need to startup on the electric motor and later changeover to steam turbine drive when the process is established. For process continuity they also need to immediately change back to electric drive in certain failure modes.

-

Pumps

Dual drive pump systems with an SSS Clutch can offer redundancy or help recover energy from the downstream pressure using a recovery turbine to make the system more efficient. The SSS Clutch will automatically connected and disconnect the secondary drive as required, ensuring continuous operation.

-

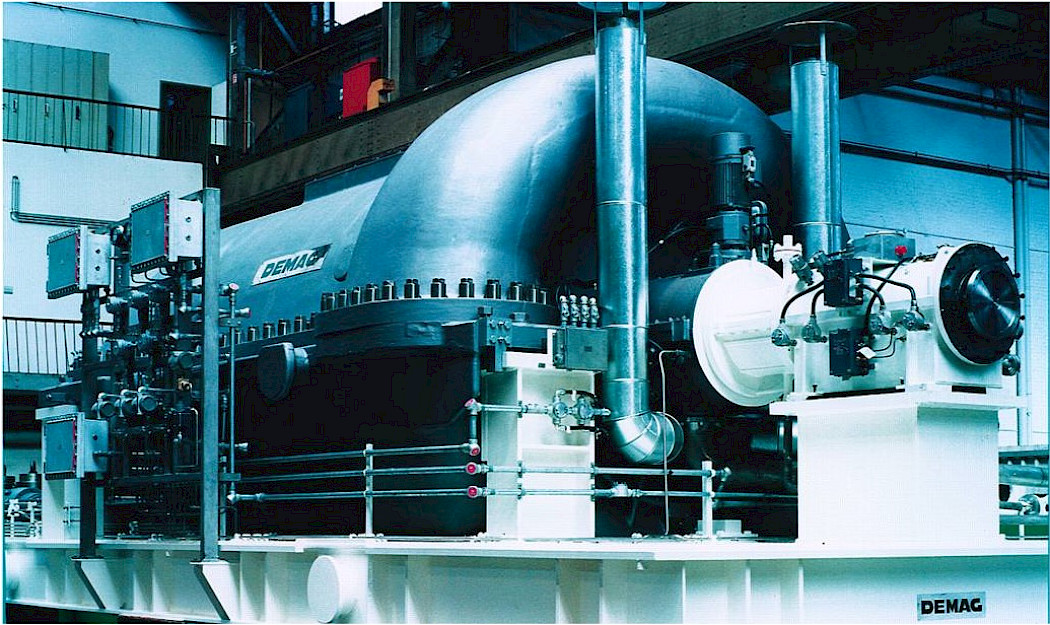

High Speed Compressors

With it’s ability to operate at high running speeds and it’s inherent reliability the SSS Clutch provides the perfect coupling for dual driven compressors.

-

Reciprocating Compressors

Often situated outside in arduous conditions and driven by reciprocating engines (gas or diesel) with potentially severe torsional vibrations particularly in failure modes, reciprocating compressors are a challenging application for other coupling types but present no problems for the SSS Clutch.

-

Arrangements

There are different SSS Clutch arrangements depending on the application and the system configuration. The clutch can be shaft mounted, self lubricated, pressure lubricated, incorporated into a gear box manufactured by others, or supplied as a standalone encased unit with integral bearings.