Triple-E Class Container Ship

The Triple-E class are among the largest container ships in the world and incorporate an SSS Clutch into their Marine Diesel Energy Recovery System to improve fuel efficiency and to lower the carbon footprint of the vessels.

The Maersk Triple-E class container ships were built by South Korea’s Daewoo Shipbuilding & Marine Engineering (DSME). They are the among the largest container ships in the world, with a container carrying capacity of 18,000 to 20,000 twenty-foot equivalent units (TEU) across the 2 different generations of construction.

Triple-E (EEE) stands for Economy of scale, Energy-efficient and Environmentally improved vessel. There are 31 vessels in the class delivered between 2013 and 2019, all of which incorporate an MHI Marine Diesel Waste Heat Energy Recovery System.

At the time of build, the vessels were the most energy efficient in the world with the lowest carbon footprint, emitting 20% less CO₂ per container shipped when compared to the most efficient container vessel available. Optimised design allows the vessel to cruise with the maximum possible load at speeds prevailing in the industry.

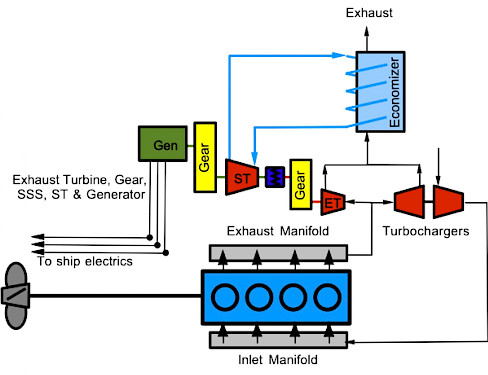

The waste heat recovery system captures the exhaust gas from the engine and uses it to run an exhaust power turbine, which in turn is used to run a generator. It cuts fuel consumption and CO₂ emissions by approximately 9%.

MHI Marine Diesel Super Waste Heat Recovery System

During low speed / power conditions the exhaust gasses from the marine diesel pass through the turbocharger to the air to avoid soot build up in the system.

When the power is at 35% or higher, the exhaust gasses pass through the economizer to generate steam which is passed through a steam turbine. The steam turbine is connected to an electrical generator through a speed reduction gearbox.

When the power is above 45%, a proportion of the exhaust gasses also pass through an exhaust power turbine which is connected to the steam turbine via an SSS Clutch, this boosts the power output of the generator. The SSS Clutch will automatically engage when the speed of the exhaust power turbine matches the speed of the steam turbine. Both 68T and 48T SSS Clutches were used on the Triple-E class, reflecting the different engine design across the 2 generations of vessel.

Electricity from the generator can be used to supply the power demand of the vessel or for additional applications like refrigeration. This system significantly improves the marine engine plant efficiency by 8% to 10% and reduces the carbon footprint of the vessel.

Marine Diesel Energy Recovery System (PDF)

Adding a power turbine to the exhaust energy recovery system boosts performance