Tolk

The addition of an SSS Clutch helped repurpose this plant to a synchronous condenser by adding a clutch to the free end of the generator.

In 2020, Xcel Energy’s 1,067MW coal fired Tolk Power Station was converted to only supply power during peak months as part of a wider plan to reduce water usage from the local aquifer and to migrate over to more renewable energy sources. Xcel Energy has also recently announced it will exit the use of coal on all generation sites by end of 2030.

Tolk is a steam turbine power plant run on dual-fuel. The primary fuel being used to power the plant is sub-bituminous coal, but the plant can also run on Natural Gas. The Tolk plant is located about 70 miles northwest of Lubbock, Texas and provided baseload power and reactive power (VARs) to the grid (ERCOT being the ISO).

SSS Clutches were considered for retrofit into the existing generators to convert to synchronous condensers so that they could supply peak power during the summer months when demand is high, but also support the local grid with inertia, reactive power and short circuit current to maintain grid stability.

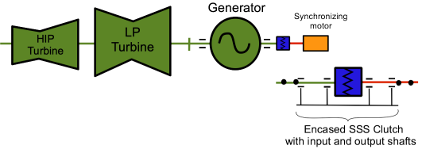

There was no space to add an SSS Clutch between the turbine and the generator, so the generator was physically disconnected from the turbine and a starting/synchronising package with a 95T Encased SSS Clutch was added to the free end of the generator.

As the turbine is still needed for generation at peak times, the starting package can be automatically disconnected from the generator with the SSS Clutch and the turbine reconnected to allow a simple changeover from synchronous condenser mode to generation mode. This change-over takes about 7 hours and can be done on a weekly basis if required but is mostly done on a seasonal basis.