Kansas City

170 MW gas turbine that can act as a synchronous condenser after 25 years, proving that SSS Clutches last for the lifetime of the power plant they are fitted to.

When the Siemens V84.3A (now designated SGT6-4000F) gas turbine generation set was installed as a peaking plant in 1997 for Kansas City Power & Light at the Hawthorn Generating Station in Kansas City, it was anticipated that the machine would only generate electricity for approx. 500 hours per year to cover both the summer and winter peak demand.

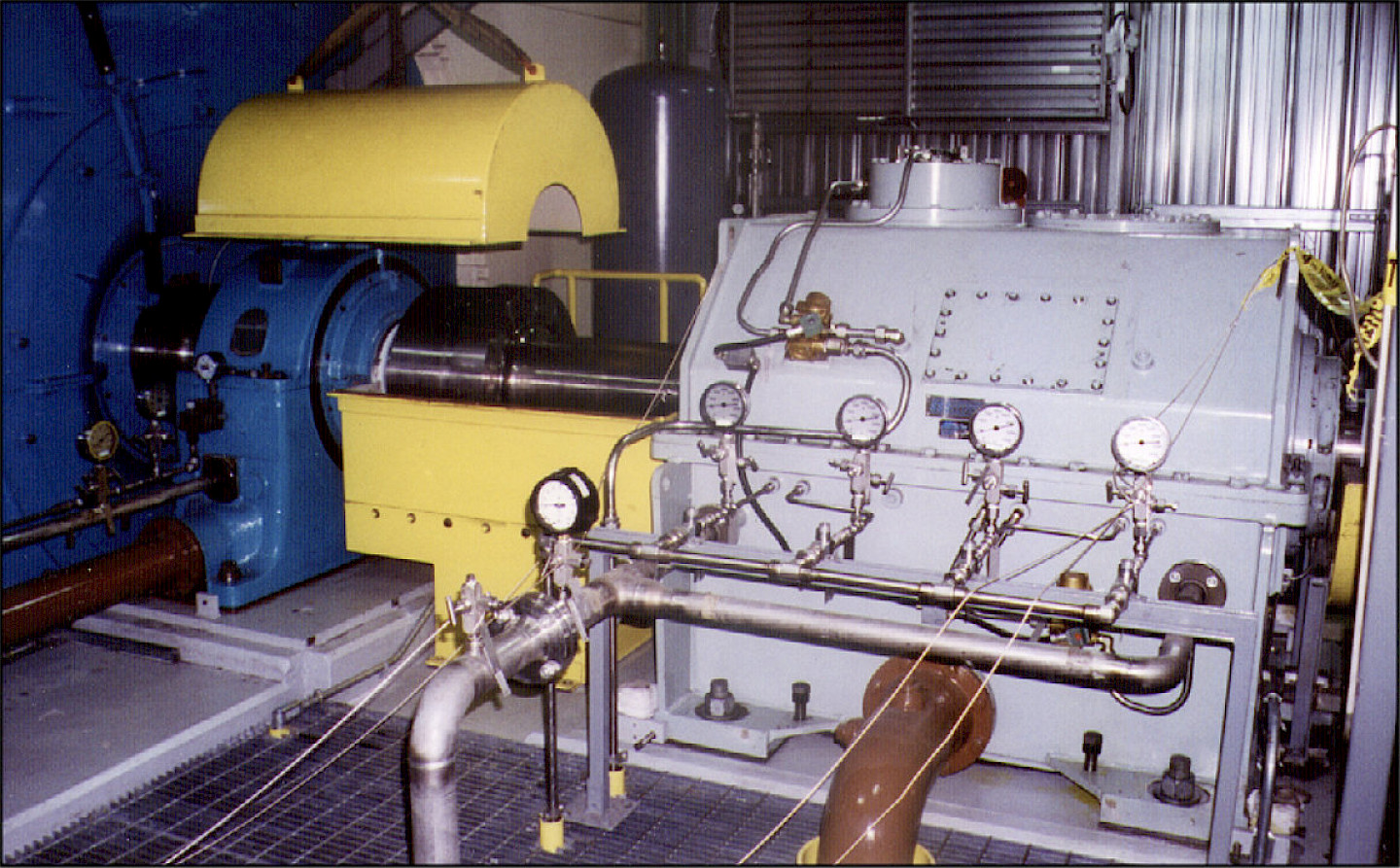

The plant was also designed to operate as a synchronous condenser for a small number of hours per year, so a 280T Encased SSS Clutch was installed to allow easy and quick disconnection of the gas turbine allowing the generator to remain synchronised and providing grid support. The relatively low marginal cost to add the SSS Clutch at this stage was easily justified.

However for 25 years the plant only operated for active power generation although it was always shutdown from November to April as the gas supply was needed for heating.

After 25 years the clutch was found to be in good condition and operating well

The new owners, Evergy Metro, decided there was a market for synchronous condensing and after 25 years of operating engaged in one position, the clutch was tested for engagement/ disengagement and overhauled to check that it had not degraded having been operating for such a long period without any service. The clutch was found to be in good condition and operating well and only required some small adjustment to the electrical switches used for position indication.

The original addition of an SSS Clutch has provided future flexibility and additional revenue for this generation plant at relatively low additional cost and shows the long-term reliability of the SSS Clutch in demanding high power applications.