Joetsu

Joetsu Thermal Power Station Unit 1 is a singleshaft combined cycle unit manufactured by Mitsubishi Power (MHI) with the world’s highest thermal efficiency at 63.62% in 2022.

The Joetsu Thermal Power Station Unit No. 1 of Tohoku Electric Power Co., Inc., has a total ouput capacity of 572MW and started operation in December 2022. The plant utlizes a M710JAC combined cycle gas turbine from Mitsubishi Heavy Industries, Ltd. (MHI) with an inlet temperature of 1650oC.

The plant attained about 25% shorter start-up time and about 3 times higher power output change rate (ramp rate) compared to a conventional combined cycle gas turbine, and has a minimum output as low as 25% of the rated output.

The unit’s high efficiency, rapid ramp rate and generation flexibility, is expected to support the introduction and expansion of renewable energy sources which have large fluctuations in power supply depending on weather conditions.

“ The most efficient combined cycle power plant is 63.62% and was achieved by Joetsu Thermal Power Station Unit No.1 operated by Tohoku Electric Power Co., Inc Japan, measured on 8 December 2022.”

Guinness World Records

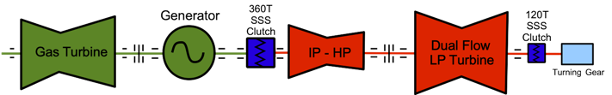

This is the first of four 360T SSS Clutches of this design, supplied in 2021 and 2022. All intended for power plants of similar power and operational flexibility.

The power generation system includes two SSS Clutches. The 360T clutch between the steam turbine and the generator allows the gas turbine to rapidly get up to speed and the generator to become synchronised to the grid. When the heat from the gas turbine exhaust has generated enough steam, the steam turbine will accelerate and the SSS Clutch will automatically engage the generator, adding to the power output and the plant efficiency.

The additional 120T clutch allows the turning gear to automatically engage and disengage with the steam turbine and to rotate the complete machine at low speed as the system cools down, preventing thermal distortion.

SSS Clutches have been used on singleshaft combined cycle gas turbine units for over 30 years with approximately 500 projects Worldwide.

Joetsu Technical Review (PDF)

Achievement of the world's highest thermal efficiency, Joestsu Thermal Power Station Unit No 1, Tohuku Electric Power Co. Inc.

Single-Shaft Combined Cycle Units Averaging 99.7% Reliability - Gas Turbine World (PDF)

Evaluation of the benefits of using a single-shaft configuration for combined cycle power generation plant