Indian Queens

140 MW peaking gas turbine plant and synchronous compensator that has been reliably supporting the grid in Cornwall, UK for over 25 years.

Indian Queens Power Station is an Open Cycle Gas Turbine (OCGT) power station located in Cornwall. The station has an output capacity of 140 MW and was specifically designed as a peak load and synchronous compensator when it was commissioned back in 1998.

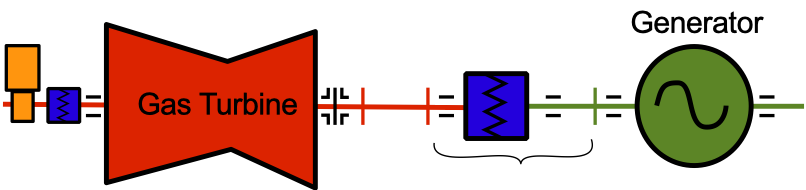

Indian Queens Power Station now predominantly provides a ‘Synchronous Compensation’ service utilising only its generator, which is uncoupled from the gas turbine using an SSS Clutch. No fuel is consumed, and no emissions are released from the site in delivering this service, which enables National Grid to efficiently control the UK transmission system voltage and frequency.

"Indian Queens Power Station is a fantastic example of where the fitting of a SSS clutch enabled the asset to be utilised for UK transmission system synchronous condensing services since 1998. With the addition of renewables onto the UK transmission system, the need for synchronous compensation services has sky rocketed over recent years. Looking back now, the design of the IQPS asset was way ahead of its time."

... Roy Bailey, Station Manager at Triton Power

Synchronous Compensation and the provision of system 'inertia’ has become a very much required National Grid service due to the recent significant addition of renewable generation and the removal of the large spinning masses on fossil fuel power stations. Synchronous compensation operation at Indian Queens Power Station has significantly increased over the past five years, with a site utilisation factor of over 90% in 2023.

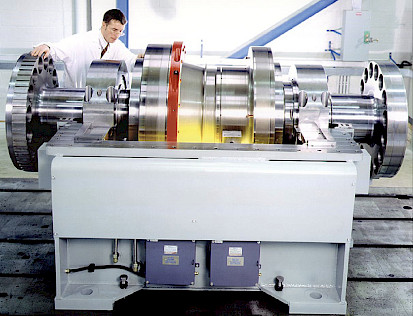

The 360FT Encased SSS Clutch installed between the GE Frame 9E gas turbine and the generator allows the generator to remain synchronised and support the grid whenever required even though the gas turbine is shutdown most of the time. As well as being an automatic freewheel to allow connection and disconnection of the gas turbine, the 360FT includes an internal thrust bearing making the clutch a fixed length and positioning the generator from the gas turbine bearing and fixed point. This arrangement allows for thermal growth and misalignment as the SSS Clutch is placed between the generator and the “hot end“ of the gas turbine.

The grid support aspect of the system is so critical that the 360FT encased clutch includes a removable thrust bearing on the output shaft so that if the gas turbine is not available it can be removed and the generator can operate as a synchronous compensator in isolation.

The plant also incorporates a Koenig starting system with a Duo 80T/55T SSS Clutch arrangement which is connected to the free or “cold end” of the gas turbine. This means the system can make a rapid conversion from synchronous mode to generation mode as the SSS Clutch will automatically engage the generator when the gas turbine matches the rotational speed of the generator.

Indian Queens Power Facility (PDF)

A Model 9E gas turbine capable of peak power generation and synchronous compensation, in Cornwall, England.