Townsville

An SSS Clutch is being retrofitted into this Siemens Energy Hybrid RGS installation so it can operate as a synchronous condenser and improve system strength without the need to move the gas turbine or the generator.

The Townsville Power Station is a gas fired power station located in Townsville, Queensland, Australia. It has two generating units with a total capacity of 242 MW and is owned and operated by RATCH-Australia. The Townsville Power Station has a Siemens Energy combined cycle plant with 1 gas turbine and 1 steam turbine.

The Siemens Energy SGT5-2000E gas turbine/generator was installed in the late 1990’s and upgraded in 2005. The Australian Energy Market Operator (AEMO) required grid operator Powerlink to improve minimum fault levels and system strength and after considering 8 different options, Powerlink decide that adding an SSS Clutch between the gas turbine and the generator was the lowest cost option to address the shortfall.

The Siemens Energy Hybrid RGS conversion using the SSS Clutch was the lowest cost option to supply the required grid services and improve system strength

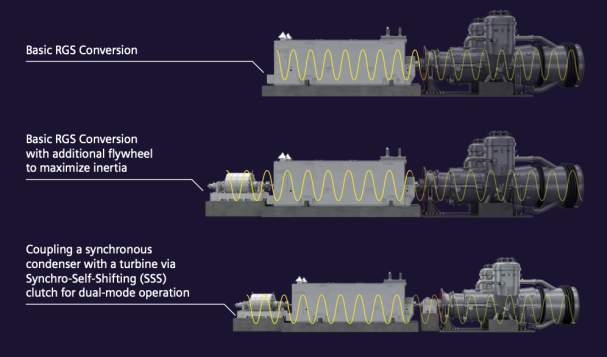

Siemens Energy will repurpose the existing system to a Hybrid Rotating Grid Stabilizer (RGS) in 2025 using an SSS Clutch so the generator can quickly switch between power generation mode and synchronous condenser mode. In synchronous condenser mode, the generator will provide rotating inertia and short circuit current to support grid system strength.

This SSS Clutch retrofit was designed by Siemens Energy and was achieved without moving or changing the gas turbine or generator rotating parts. The oil system was installed under the shaft line between the gas turbine and the generator, so is being removed out to one side leaving space for a concrete plinth to be added to support the SSS Clutch. The Size 280T SSS Clutch is mounted in a casing with two tilting pad journal bearings to support the SSS Clutch so that no additional radial loads are imposed on the gas turbine or the generator.

Siemens Energy carried out rotor dynamic studies working with SSS to select the bearing characteristics. SSS supplied the casing shaft and bearings and the gas turbine air intake is being modified by Siemens Energy to make space for the SSS Clutch.

The Queensland SuperGrid - Power Magazine (PDF)

How the Townsville project is supporting the drive to more renewable energy