Tennessee Valley

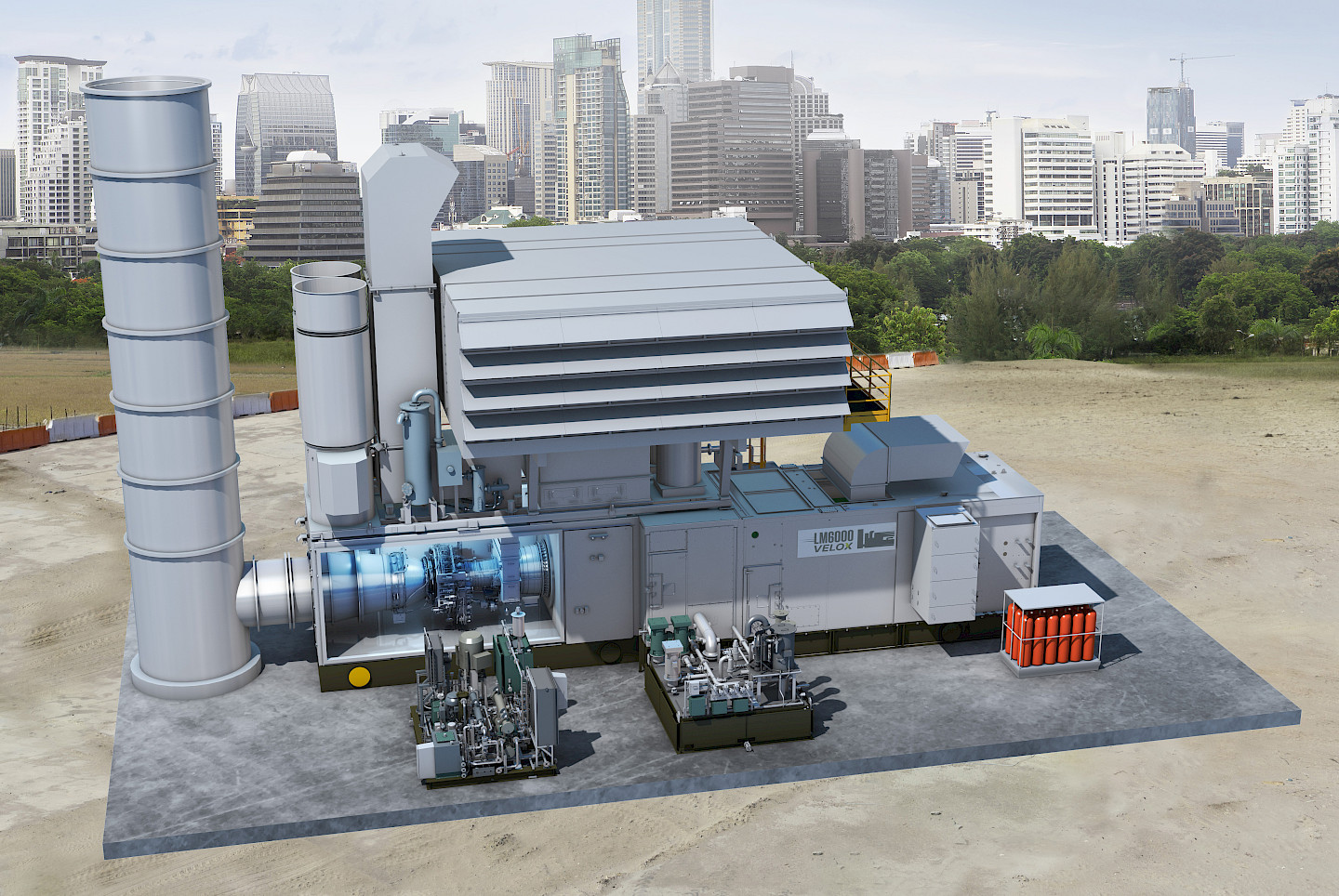

500 MW of flexible generation capacity added by the Tennessee Valley Authority (TVA) using GE Vernova LM6000 Aeroderivative Gas Turbines with SSS Clutches integrated into the gearbox.

Tennessee Valley Authority (TVA) is placing 10 Aeroderivative gas turbine and generator sets at the Johnsonville Plant in middle Tennessee. Construction is underway and the units are scheduled to be operational by the middle of 2025. The 10-unit project will add 500 MW of new modern power generation and is a first for TVA.

With the increase in intermittent renewable generation and the closure of coal fired generation sets, these peaking power plants are required for security of supply both in terms of active power to meet demand and also for grid stability and support.

The GE Vernova Aeroderivative gas turbines allow for extreme generation flexibility and are able to come up to full power within 5 minutes to respond to rapid power demand changes. The units are fitted with an SSS Clutch, so they are able to operate as synchronous condensers when not delivering active power. The turbines also allow the flexibility of using carbon-free hydrogen in the future.

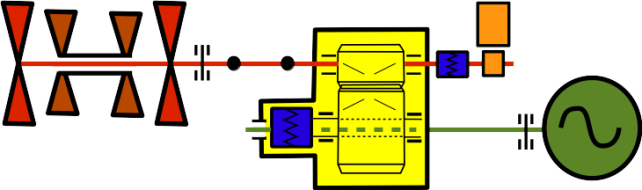

In synchronous condenser mode, the SSS Clutch will quickly and easily disconnect the gas turbine drive and leave the generator synchronised to the grid providing reactive power for voltage control and inertia for frequency stabilization.

TVA expect about 300 starts and 1000-2000 generating hours per year per unit and even if the generating hours reduce, these machines will have an important role to support the grid. So important is this grid support, that TVA expect that 2-4 units will continuously operate in synchronous condensing mode, unless they are running for generation needs.

The GE Vernova LM6000 gas turbine is connected to the generator through a speed reducing gearbox. The 240T SSS Clutch is integrated into the gearbox mounted on the gas turbine side of the main gear wheel in a quill shaft configuration. In this way the addition of the clutch does not add any extra length/footprint to the machine.

The 240T SSS Clutch can engage at any generator speed and therefore changeover from synchronous condensing mode to power generation mode can occur seamlessly without disconnecting the generator from the grid. The SSS Clutch includes an internal thrust bearing so that the clutch is a fixed length and locates the generator from the gas turbine thrust bearing.

Why the Renewable Build Out Needs Gas Firming - Modern Power Systems (PDF)

Why it is important to balance the rapid expansion of renewables with peaking power plant and synchronous condensing