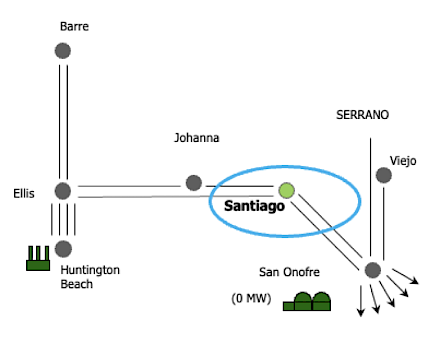

Santiago

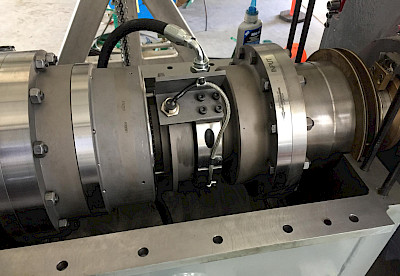

SSS Clutches were selected for 3 acceleration packages, because they allowed the synchronous condenser to disconnect from the pony starter motor and have lower friction losses.

In 2016, Southern California Edison (SCE) needed to strengthen the grid and improve reactive power in the region due to the closure of the San Onofre Nuclear Power Station and a significant investment in new high voltage overhead lines to connect the single largest wind turbine project in the USA. The solution was to add a dedicated synchronous condenser to the Santiago substation.

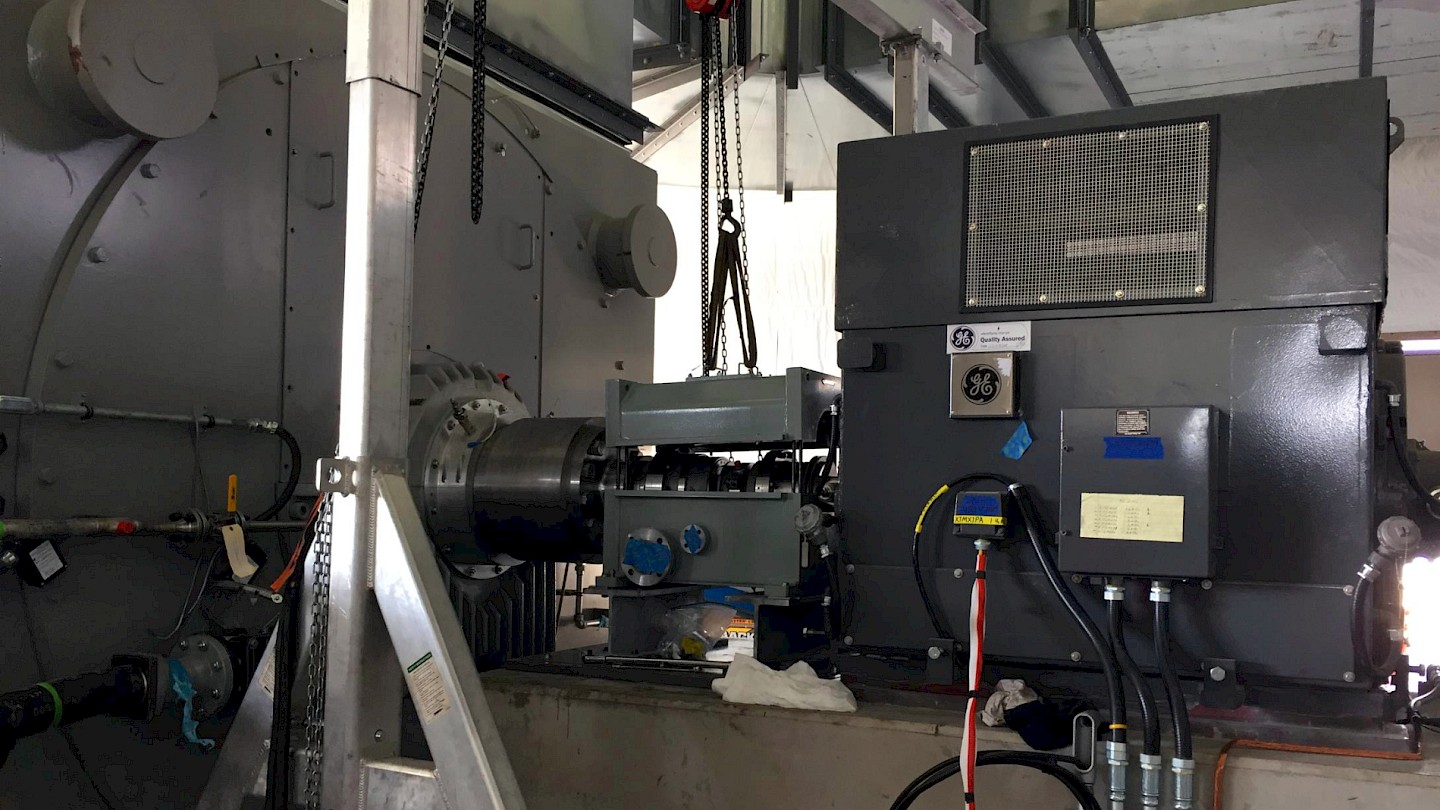

GE was the selected vendor and supplied 3 x 81MVAR Synchronous Condensers (SC) for the project. GE determined that the most cost effective and reliable way of accelerating and synchronising these machines was to use a pony motor system comprising an induction motor driven by a Variable Frequency Drive (VFD) system.

The energy saving achieved by fitting the clutch more than paid for the clutch investment over the life of the unit and allowed a simpler pony motor to be used.

Their first option was to connect the induction motor to the synchronous condenser using a flexible coupling. However this would mean the pony motor was spinning continuously whenever the SC was operating causing a small but significant power loss.

A cost benefit analysis quickly showed that removing these losses by fitting a clutch, which has very much smaller losses, would quickly pay for the small additional cost of the clutch system compared with the flexible coupling. In addition the use of an SSS Clutch allowed a simplified induction motor to be used as a continuously spinning motor has to be more sophisticated and regularly maintained to avoid compromising the availability of the SC.

Another very significant advantage of disconnecting the pony motor with a clutch is simplifying the rotor dynamics. The SC is added to increase system strength of the grid often in areas where there are significant inverter based renewables connected by power electronics. These areas often have significant harmonics in the electrical system which can cause fatiguing torques in the shaft system, and disconnecting the pony motor reduces the highly stressed parts of the system.

Additionally in the case of a major system fault (when the SC is there to generate short circuit currents) the fault torques are not passed to the pony motor avoiding the need to consider that part of the system.

In this installation the SSS Clutch is a Spacer Clutch design which acts like a double element flexible coupling directly replacing the coupling that would be in this position if it was solidly coupled. The length of the clutch is similar to the flexible coupling. The SSS Clutch requires a small oil flow from the main oil system and in this case SSS provided the oil tight casing to surround the clutch acting like a coupling guard.