Eskom

7 heavy duty peaking gas turbines each rated at 176 MW fitted with SSS Clutches to allow synchronous condensing operation, supplied to Eskom the National Utility in South Africa.

South Africa’s National utility Eskom generates over 90% of the country’s electricity and in 2006 they invested in 1000 MW of additional power generation. With the main base load Power Plants at the end of long transmission lines at the other end of the country, the local grid in Western Cape needed local voltage support as well as extra power at peak times.

SSS has a long history of supplying cluthes into South Africa going back to 1966 when 2 retrofit clutches were supplied onto 15MW Rolls Royce Avon Gas Engines. In total there have been 28 installations into various generation sites.

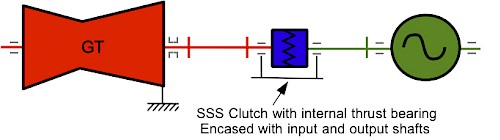

Seven SGT5-2000E Open Cycle Gas Turbine (OCGT) Generators with SSS 280T Encased Clutches were installed at the Ankerlig and Gourikwa Power Stations and became operational in 2007. The Gas Turbines can be converted to Combined Cycle (CCGT) units increasing power output and efficiency if required in the future.

The SSS Clutch allows the power station to operate as both Peaking Power Plant and in Synchronous Condenser operation mode. The clutch only disengages the drive when the rotational speed of the gas turbine is less than the rotational speed of the generator. This means the gas turbine can be easily disconnected, leaving the generator synchronised to the grid providing system inertia, short circuit power and reactive power for local grid strength and stability.

To return to generation, the generator is disconnected from the electrical grid, reduced to tuning gear speed and the clutch is engaged and locked. The generator is then connected to the grid again to accelerate the assembly while the gas turbine is brought up to full power.

As well as being an automatic freewheel to allow reliable and easy connection and disconnection of the Gas Turbine, the SSS Clutch design includes an internal thrust bearing making the clutch a fixed length and positioning the generator from the gas turbine thrust bearing and fixed point.

Synchronous Delivery at Eskom - Utility Management (PDF)

Eskom adds 1000MW of generating capacity with synchronous condensing for grid stability